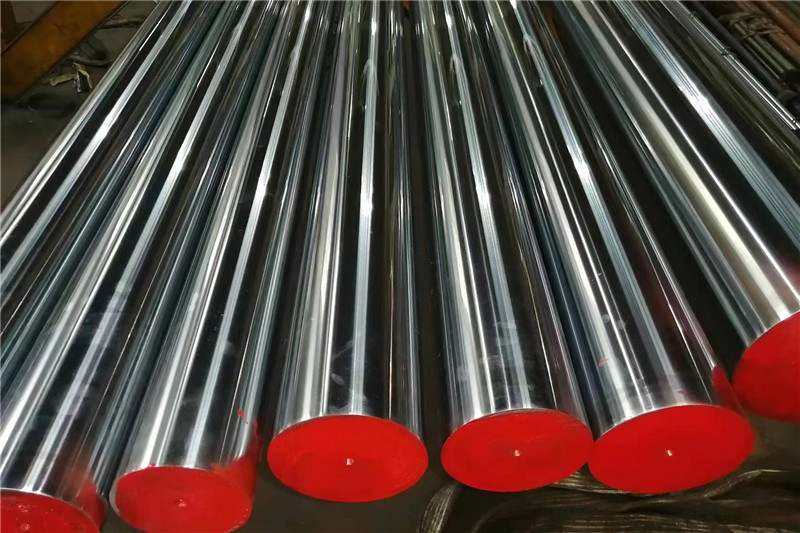

• Boitsebiso: JIS S45C, SAE1045, DIN CK45, EN8

• Kopo: Hydraulic/ Pneumatic Cylinder, Machine Machine, Hydraulic/ Pneumatic Auto Machine, Plastic Ente Molding Molding Machine.

• Botenya ba Lera la Chrome:

<Φ20 15μm mets.

≧ Φ20 20μm min.

• Ho thatafala ha Lera la Chrome: HV850 min.(0.1)

• Ho Hlolla ha Sebaka: Ra 0.2μm max.

• Ho Nepaha ha Diameter ka Ntle: ISO h7,f7,h8,f8,g6

• Ho otloloha: 0.3mm/M

• Ho pota-pota: 1/2 Mamello

Lithupa tsa rona tsa chrome li fana ka nako e telele, ho nepahala le ho hanyetsa kutu, e leng se etsang hore e be khetho e nepahetseng bakeng sa mechini le lisebelisoa tse boima.Lithupa tsa rona li entsoe ka thepa ea boleng bo holimo 'me li entsoe ka boqhetseke ho fihlela litekanyetso tse thata ka ho fetisisa tsa tlhahiso.Li etselitsoe ho mamella maemo a thata ka ho fetisisa a ts'ebetso, ho kenyelletsa le mocheso o feteletseng, khatello e phahameng le meroalo e boima.Sephetho ke sehlahisoa se ka tšeptjoang le se tšoarellang nako e telele, se u fang khotso ea kelello le tlhahiso e ntlafetseng.

Lithupa tsa rona tse thata tsa chrome li fumaneha ka mefuta e fapaneng ea boholo le litlhaloso ho lumellana le litlhoko tsa hau tse ikhethileng.Hore na o hloka thupa e nyane ea bophara kapa e kholoanyane bakeng sa lits'ebetso tse boima, re na le sehlahisoa se phethahetseng bakeng sa hau.Re boetse re fana ka litharollo tsa tloaelo, tse u lumellang hore u hlophise lithupa tsa hau tsa chrome ho fihlela litlhoko tsa hau tse ikhethileng.Ts'ebetso ea rona ea chrome plating e tsoetse pele haholo, e netefatsa hore ho roala ho khomarela hantle holim'a melamu.Sena se etsa hore ho be le moaparo o ts'oanang le o tsitsitseng o fanang ka ts'ireletso e phahameng ea ho apara le tšireletso ea kutu.E boetse e felisa tlhokahalo ea mafura a eketsehileng, ho fokotsa litšenyehelo tsa tlhokomelo le ho fokotsa nako.Lithupa tsa rona tse thata tsa chrome li loketse mefuta e mengata ea lisebelisoa, ho kenyelletsa le li-cylinders tsa hydraulic, li-shafts tsa pompo, lithupa tsa piston, le tse ling.

Li boetse li loketse ho sebelisoa indastering ea likepe, tsa sefofane le tsa merafo, tse fanang ka ts'ebetso e ikhethang libakeng tse thata.Ntle le ts'ebetso ea bona e ikhethang, lithupa tsa rona tse thata tsa chrome le tsona li na le litšenyehelo tse phahameng haholo.Ba fana ka boleng bo botle ba chelete, ba fana ka bophelo bo bolelele ba ts'ebeletso le litlhoko tse tlase tsa tlhokomelo.Li boetse li thusa ho fokotsa litšenyehelo tsa sistimi ka ho fokotsa tlhoko ea ho lokisoa khafetsa le ho nkeloa sebaka.Haeba o hloka lithupa tsa boleng bo holimo tse entsoeng ka chrome bakeng sa lits'ebetso tsa hau tsa indasteri kapa tsa haeteroliki, se shebe hole ho feta lihlahisoa tsa rona.Lithupa tsa rona li fana ka ts'ebetso e ikhethang, nako e telele, le boleng ba chelete, e ba etsa khetho e nepahetseng bakeng sa lits'ebetso tse batlang.Ikopanye le rona kajeno ho ithuta haholoanyane ka mefuta ea lihlahisoa tsa rona le hore na re ka u thusa joang ka projeke ea hau e latelang.

| Kereiti ea tšepe | C45E (EN 10083) |

| Diameter Range | Ø12 ho isa ho Ø120 mm |

| Sehlopha sa Mamello | ISO f7 |

| Ho pota-pota | Mamello ea bophara / 2 |

| Bolelele bo Tloaelehileng | Bakeng sa Ø <60 limilimithara: 5600 - 6200 limilimithara Bakeng sa Ø ≥ 60 mm: 5800 - 6200 mm Ka kopo: bolelele bo khethehileng ho li-diameter tsohle |

| Bokhopo ba Sekaho | Ra max.0.2 µm |

| Bothata ba Sefahleho | mets 55 HRC |

| Botebo bo thata ba Lera | 2.0 limilimithara |

| Botenya ba Layer ea Chrome | < Ø20 limilimithara: min.15µm ≥ Ø20 mm: min.20µm |

| Bothata ba Lera la Chrome | min.900 HV (0,1) |

| Ho otloloha | ≤ Ø16 limilimithara: boholo.0.3 limilimithara: 1000 limilimithara > Ø16 limilimithara: boholo.0.2 limilimithara: 1000 limilimithara |

| Ø | > 10 mm ≤ 18 mm | > 18 mm ≤ 30 mm | > 30 mm ≤ 50 mm | > 50 mm ≤ 80 mm | > 80 limilimithara ≤ 120 limilimithara |

| f7 | -16 μm -34 μm | -20 μm -41 μm | -25 μm -50 μm | -30 μm -60 μm | -36 μm -71 μm |

Re nahana ka tieo hore re na le bokhoni bo felletseng ba ho u fa sehlahisoa se khotsofatsang.Ke lakatsa ho bokella lintho tse u tšoenyang le ho theha kamano e ncha ea nako e telele ea lerato.Kaofela re ts'episa haholo: theko e tšoanang e ntle, e rekisoang hantle;theko e nepahetseng ea ho rekisa, boleng bo betere.